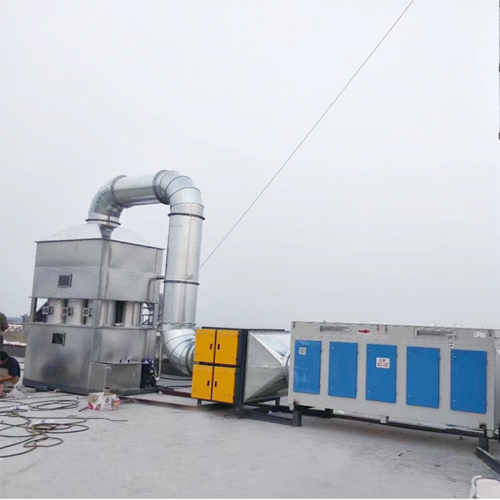

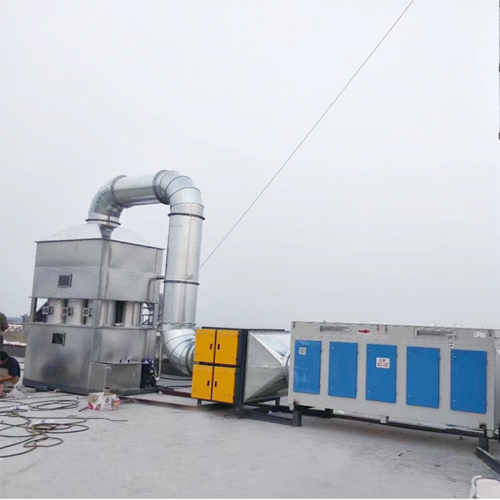

Printing plant workshop in the production process of a large number of the use of ink, fast drying agent, cleaning agent, binding little adhesive, which ink flavor zui big, gravure printing ink benzene, but toxic, can cause benzene poisoning, resulting in blood disease. The harmfulness of working in this environment is self-evident, and the pungent smell directly affects the normal production operation efficiency.

The purification mechanism of industrial waste gas treatment equipment designed by hebei hengning environmental science and technology co., LTD includes two aspects:

1. In the process of plasma generation, the instantaneous high energy generated by high-frequency discharge can unlock the chemical energy of some harmful gas molecules and decompose them into elemental atoms or harmless molecules.

2. plasma contains a large amount of high energy electron, positive and negative ions, excited state particles and has a strong oxidizing free radicals, the activity of the particles and part of the waste gas molecular collision combination, the paper mill waste gas treatment equipment manufacturer under the effect of electric field, the gas molecules in excited states, more than when the energy of gas molecules get keys to the binding energy of the molecules, exhaust gas of molecules bond rupture, is directly decomposed into elemental atoms or harmless gas molecules made up of a single atom. At the same time, a large number of ·OH, ·HO2, ·O and other active free radicals and highly oxidized O3 can react with harmful gas molecules and finally generate harmless products.

"Ion dust collection technology" special ion dust collection purification device USES high intensity electric field to capture dust particles in strong electromagnetic field, effectively kill bacteria, so that the air through the complete purification. Can remove pollen, dust particles, kill bacteria. Reduce cost and improve production efficiency: this device mainly solves the problem of dynamic sterilization, disinfection, dust removal, odor removal and organic gas removal in the workshop environment when people are working, so as to achieve harmless to human body and avoid the cross-spread of secondary pollution of bacteria in the air. In addition, the entire air environment purification does not need to stop production, which improves work efficiency and reduces operating costs.