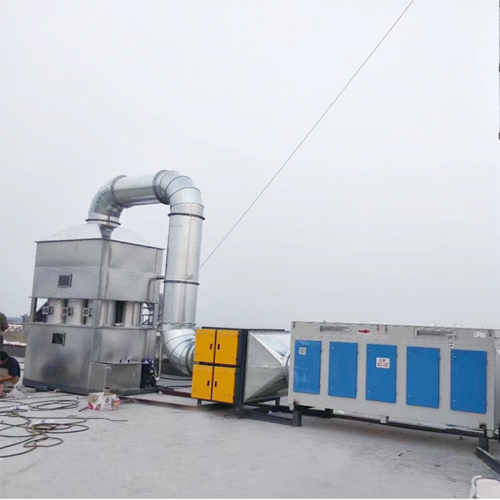

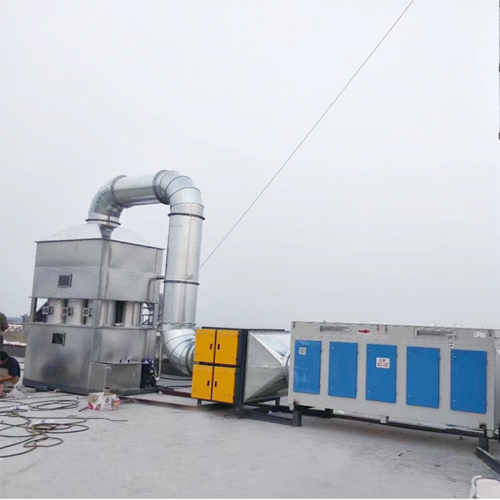

Organic waste gas treatment equipment is a kind of activated carbon purification treatment of organic waste gas dry type waste gas purifier, by the box and adsorption unit, combined with the duct fan into the purification system, the main use of performance activated carbon to adsorb organic waste gas molecules, so that it and harmless other separated, to achieve the purpose of purifying the air.

1. Activated carbon adsorption method

The effective absorption of activated carbon can effectively absorb organic waste gas containing benzene and aromatic hydrocarbons produced by chemical workshop, with efficiency, low cost and other points, the disadvantage is that the regeneration difficulty needs to replace activated carbon adsorbent regularly.

2. Photocatalytic oxidation

Using special ultraviolet band under the action of special catalytic oxidant, the waste molecules are broken up and REDOX in one step. Discarded molecules first go through a special band of ultraviolet light to destroy the molecular structure, breaking the molecular connection. At the same time, oxygen and water molecules in the air catalyze to ozone, which oxidizes aromatic hydrocarbons in organic waste gas, thus achieving the effect of air purification. It has stable performance and long service life of printing machine exhaust treatment equipment manufacturers.

3. Low temperature plasma technology

Through the discharge, the active chemical ions are generated in the medium, which react with the active groups in the waste gas and eventually turn into pollution-free substances such as carbon dioxide and water, so as to achieve the purpose of purifying the air. With a wide range of applications, purification efficiency, low operating costs, the disadvantage is that most of the medium is chemicals, there are certain hidden dangers.

4. The combustion method

Organic waste gas and fuel are fully mixed in the case of temperature to achieve combustion, can be used for less density combustible organic gas, with purification efficiency, exhaust gas treatment thoroughly point, but the equipment is vulnerable to temperature damage, easy to cause secondary pollution.

5. Biological methods

There are a variety of microorganisms in nature, and almost all inorganic and organic waste gas can be bioconverted into harmless substances. Compared with other methods, it has simple equipment, safe and reliable, and no secondary pollution. However, the current technology is not mature enough to recycle pollutants and observe them in real time.

First, performance, the purchase of the organic waste gas treatment equipment to pay attention to the performance of the line, because the equipment is used in a special environment, the nature of the work is relatively special, so the performance to the surface, otherwise can not play a role in the application. And the performance is affected, also can cause the service life to reduce greatly.

Second, the structure, only quality organic waste gas treatment equipment in use can play a role in order to ensure that people can play a role in the treatment of waste gas. And quality equipment is usually more reliable, stable, safe structure, so in use can reduce the occurrence of many faults.